In recent news, ***company name removed*** has announced the introduction of their new automatic green sand foundry machine, which is set to revolutionize the aluminum casting industry. With this innovative technology, the company is poised to further enhance its capabilities and meet the growing demand for high-quality aluminum castings across various industries.

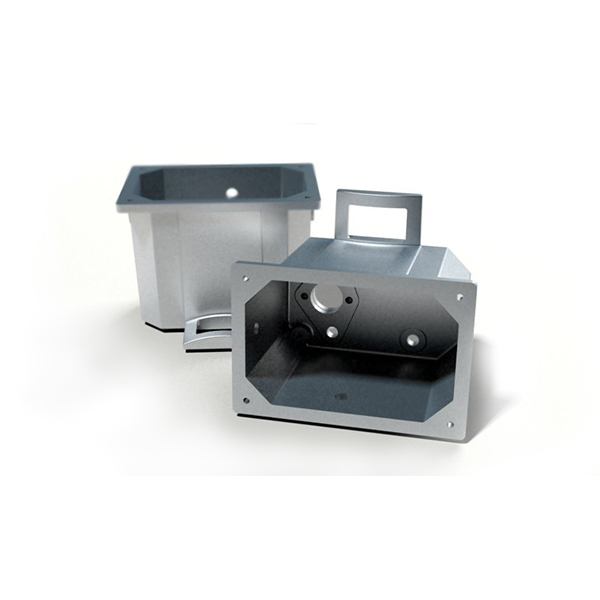

The automatic green sand foundry machine represents a significant advancement in the production of aluminum castings. It is designed to streamline the manufacturing process, improve efficiency, and ensure consistent quality in every casting produced. This state-of-the-art machine is equipped with advanced automation and control systems, allowing for precise molding and casting operations.

One of the key advantages of the automatic green sand foundry machine is its ability to significantly reduce lead times and production costs. By automating the molding and casting processes, the machine eliminates the need for manual labor and minimizes the risk of errors. This not only speeds up production but also enhances the overall quality and consistency of the castings.

Additionally, the machine is capable of producing a wide range of aluminum castings with varying complexities and specifications. Whether it is for lighting, medical equipment, transportation, 3C products, hardware, electrical accessories, or machinery parts, the automatic green sand foundry machine can accommodate diverse casting requirements with precision and efficiency.

"We are thrilled to introduce the automatic green sand foundry machine as part of our ongoing commitment to delivering excellence in aluminum casting solutions," said a spokesperson for ***company name removed***. "This cutting-edge technology represents a significant milestone for our company and underscores our dedication to meeting the evolving needs of our clients worldwide."

The introduction of this innovative machine aligns with ***company name removed***'s strategic vision to stay ahead of the curve in the aluminum casting industry. By investing in advanced manufacturing technologies, the company aims to strengthen its position as a leading provider of high-quality aluminum castings for a wide range of applications.

Furthermore, the automatic green sand foundry machine reflects ***company name removed***'s commitment to sustainability and environmental responsibility. The machine is designed to minimize material wastage and optimize energy consumption, contributing to a more efficient and eco-friendly manufacturing process.

Looking ahead, ***company name removed*** is confident that the automatic green sand foundry machine will not only elevate its production capabilities but also open up new possibilities for collaboration and innovation in the aluminum casting sector. By leveraging this state-of-the-art technology, the company is well-positioned to meet the increasing demand for premium aluminum castings in the global market.

As the company continues to push the boundaries of what is possible in aluminum casting, the unveiling of the automatic green sand foundry machine signifies a bold step towards a more advanced, efficient, and sustainable future in the manufacturing industry.

In conclusion, the introduction of ***company name removed***'s automatic green sand foundry machine marks a significant milestone in the aluminum casting industry. With its advanced automation, precision molding, and enhanced efficiency, this innovative technology is set to redefine the production of high-quality aluminum castings for diverse applications. As the company remains dedicated to meeting the evolving needs of its global clientele, this latest addition underscores its commitment to excellence, sustainability, and innovation in manufacturing.