The aspheric first surface is molded, and the spherical second surface is either molded or ground and polished. The lenses are ideal for laser diode collimating and focusing, digital projection, and microscopic measurement. The half-ball lenses are molded from B270, borosilicate, and F2 class materials with diameter sizes of 3, 4, 5, and 6 mm, with standard, truncated, and extended center thickness. The hemisphere first surface is molded, and the plano second surface is ground and polished. These lenses find their applications in LED lighting, fiber communications, endoscopy, microscopy, optical pickup devices, and laser measurement systems.

Moulded Optics GmbH has been serving clients all over the world as a professional aluminum casting foundry with a built reputation in China. The company provides raw or machined casting to top tier and OEM manufacturers. Moulded Optics GmbH's products are used in lighting, medical equipment, transportation, 3C products, hardware, electrical accessories, and machinery parts.

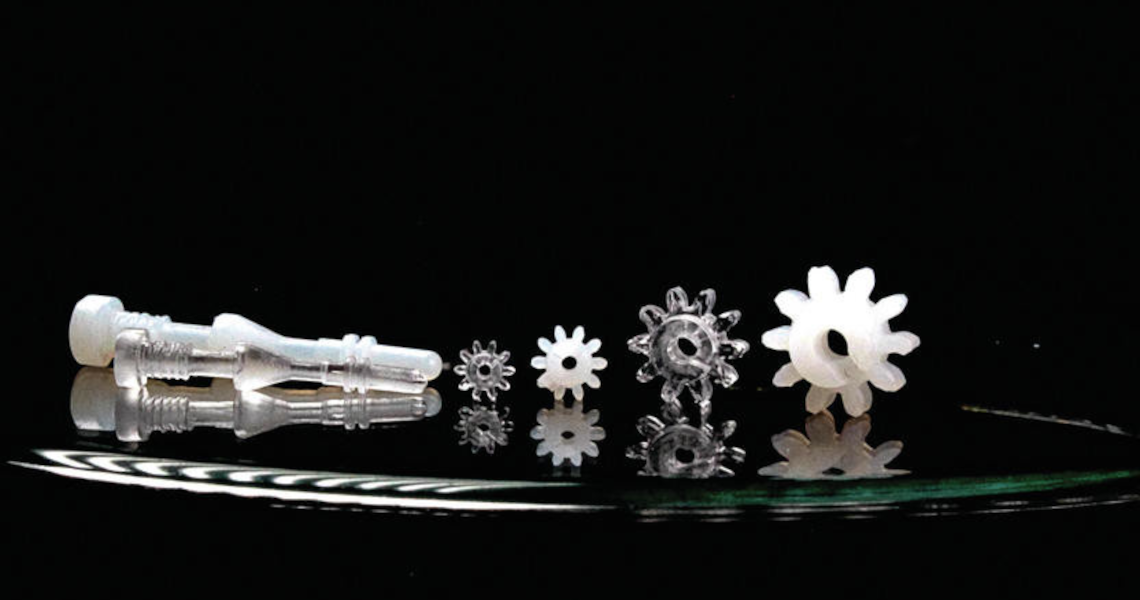

The emergence of molded lenses becomes necessary for mass production since they are cost-effective and easy-to-produce. In contrast, conventionally produced lenses require multiple-step processes, making them expensive for mass production. Molded lenses also have a lower surface roughness when compared to conventionally produced lenses, resulting in improved light transmission and image quality.

Molded aspheric lenses are in high demand as they address the issues faced by their conventionally produced counterparts. Conventional aspheres are only available for select specifications, and they require expensive grinding and polishing. Molded aspheres, on the other hand, can be produced in great volumes, and the cost of production is lower.

Aspheric lenses have an advantage over conventional spherical lenses, as they can correct spherical aberration. Spherical aberration is an optical error that causes a sphere-shaped object to appear blurry at the edge of the lens, and aspheric lenses reduce this error. They are used in high-performance lenses for cameras, telescopes, and other optical systems.

Molded glass lenses have distinct advantages over conventional lenses. They can be produced in high volumes cost-effectively, have lower surface roughness, and are capable of correcting optical errors such as spherical aberration. They are useful in various applications such as laser diode collimating, digital projection, and microscopic measurement.

In conclusion, Moulded Optics GmbH's molded glass lenses have gained traction in the market due to their cost-effectiveness, easy manufacturing process, and improved image quality. As the demand for high-performance optical systems continues to grow, molded glass lenses provide a viable solution. Moulded Optics GmbH's contribution to the market shows how manufacturing innovations can impact various industries positively.